Stainless steel profiles are finishing elements with fixed and defined shapes and sizes that are applied at an acute angle or on a flat surface such as a cladding base or on elements of a structure.

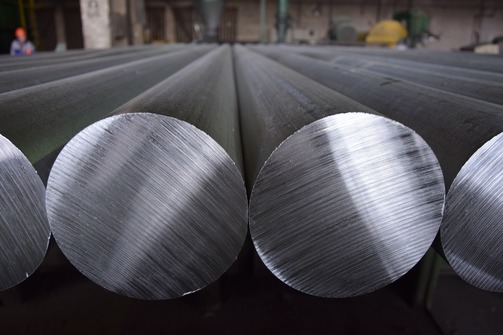

Different forms of stainless steel profiles obtained by drawing or hot rolling are available to meet various needs and application configurations such as: U-shaped stainless steel profiles, square tubes, rectangular tubes…

Stainless steel profiles are available in brushed or polished finishes, and their unique properties depend on their use: stainless steel 304 for indoor use; for outdoor use, stainless steel 316 designation.

Stainless steel profile: the various uses?

In the industry, stainless steel is used in food production equipment such as refrigeration systems and plumbing. You can also use it in processes of production, processing, storage, preparation, and distribution.

To preserve the lifespan of the steel in industrial uses, it is necessary to know the correct form for its processing. Tanks, condensers, and any other equipment must be cleaned frequently. However, stainless steel products play a very important role, as they help improve the hygiene of kitchens, restaurants, and other places.

But architecture is another field that adopts stainless steel in its production line. Considered a noble material, it has found its place in various areas outside the kitchen, where it was previously accustomed. Therefore, regardless of its shape, the U-shaped stainless steel profile or others is an ideal material to apply in many environments.

Indeed, these materials are found in brushed or lacquered decorative pieces that provide ornaments with an aesthetic look. It is also widely used in the production of furniture and home accessories. The stainless steel profile offers three decorative characteristics: functionality, quality, and beauty!

Thus, the stainless steel profile is used by architects and civil engineers due to the privileges it provides and its manufacturing processes. Coils, sheets, ribbons, and pipes are forms of this material that enable good creations in the field of construction. As you can see, the stainless steel profile has many uses and offers incredible advantages. Therefore, to obtain quality results, it is necessary to know how to use it according to needs and opportunities.

It is very crucial to master and understand the uses of the stainless steel profile to ensure the longevity of this blend. In addition to identifying the ideal type that corresponds to each application target.

Stainless steel vs aluminum

Stainless steel is a type of steel. It is called stainless because it contains more than 10.2% chromium and less than 1.2% carbon. This ratio makes it very resistant to rust and corrosion without requiring additional treatment. Stainless steel has many advantages, namely:

● Cheap compared to galvanized steel

● Strong and easily manageable

● Durable and easy to clean

● Hygienic

● Aesthetic

Aluminum is also one of the most used non-ferrous metals in metalworking. It is included in the metal recycling process, making it one of the most environmentally friendly sustainable metals on the market. Aluminum has many advantages:

● A bit expensive

● Strong and very malleable

● High thermal insulation and waterproof

● Resists corrosion well

● Stable and doesn’t damage with heat or humidity

While galvanized steel is ideal for your most robust constructions, aluminum will be more useful for your household appliances. Stainless steel has many practical uses. For more information on the best material for your work, consult an expert. Find your nearest metallurgist through our online directory.